|

- for outside surfacing PP-6-01 ·

PP-6-02 ·

PP-6-03 ·

PP-6-03M ·

PP-6-04 ·

PP-7 ·

PP-7-01 ·

PP-7-02 ·

PP-8 ·

PP-9S

- for inside surfacing PP-12 ·

PP-12-01 ·

PP-14 ·

PP-15

- for special purpose

PP-9L ·

PP-21 ·

PP-21-01 ·

PP-25

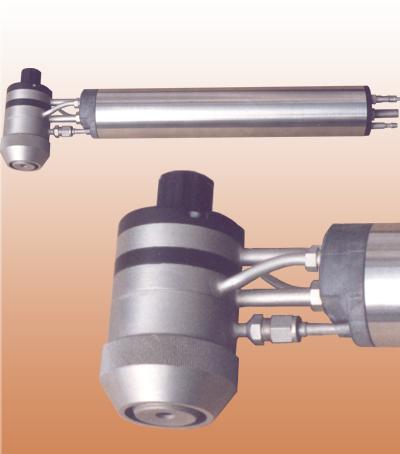

| PP-6-03 |

Universal

PTA torch for outside and inside surfacing |

PP-6-03 PTA torch is designed for PTA-process

mainly under the conditions of heavy-duty industrial

applications.

It consists of two parts - PTA torch and

holder with horizontal arrangement of communications.

The PTA torch is attached to the holder by supply

tubes and fixed by four screws. This original attachment

unit permits to connect or disconnect the PTA torch

for service very quickly and take aside from the hot

surfacing zone all its service lines.

The PTA torch complete set includes two couples of

plasma and focusing nozzles of different dimensions.

Indeed, there are two torches in one. Necessary combination

of nozzles is selected according to required power and concentration

of plasma arc (see Table I.).

It is possible to deposit Fe-, Ni- and Co- based alloys

on working faces of different parts to protect them against

wear, corrosion etc. Pure argon (99,995% Ar) is used as

a working gas. |

I. Recommended combination of nozzles

| Outlet

size: plasma/focusing nozzle, mm/mm |

Main working parameters |

Powder

particle size, mkm |

| Transferred

arc current, A |

Gas

flow rate, L/min |

| plasma |

transport |

shielding |

| 3 / 6* |

30 - 150 |

1,0 |

3,0 |

8,0 |

63 - 125 |

| 4 / 8 |

80 - 220 |

2,0 |

3,0 |

10,0 |

63 - 200 |

| 5 / 9 |

150 - 300 |

2,5 |

3,5 |

10,0 |

80 - 200 |

| 6 / 10* |

200 - 350 |

3,0 |

4,0 |

12,0 |

80 - 200 |

* - available at request of Customer.

II. Technical data of PP-6-03 PTA torch

| Current of pilot arc,

A |

30 - 50 |

| Current

of transferred arc, A |

30 - 350 |

| Additive powder

deposition rate, kg/h |

0,5 - 8,0 |

| Powder particle

size, mkm |

63 - 200 |

| Powder losses, % |

<

5 |

| Total gas flow rate (argon),

l/min |

12 - 19 |

| Cooling water flow rate,

l/min |

>

6 |

| Diameter x height, mm |

60 õ 114 |

| Weight without holder(with holder), kg |

1,2(2,5) |

| III. PP-6-03 PTA Torch

schematic view |

|

| Example of application |

|

|

- for outside surfacing PP-6-01 ·

PP-6-02 ·

PP-6-03 ·

PP-6-03M ·

PP-6-04 ·

PP-7 ·

PP-7-01 ·

PP-7-02 ·

PP-8 ·

PP-9S

- for inside surfacing PP-12 ·

PP-12-01 ·

PP-14 ·

PP-15

- for special purpose

PP-9L ·

PP-21 ·

PP-21-01 ·

PP-25

|