|

- for outside surfacing PP-6-01 ·

PP-6-02 ·

PP-6-03 ·

PP-6-03M ·

PP-6-04 ·

PP-7 ·

PP-7-01 ·

PP-7-02 ·

PP-8 ·

PP-9S

- for inside surfacing PP-12 ·

PP-12-01 ·

PP-14 ·

PP-15

- for special purpose

PP-9L ·

PP-21 ·

PP-21-01 ·

PP-25

| PP-21 |

PTA

mini-torch PTA torch for surfacing in hard-to-reach places of different parts |

PP-21

PP-21-01

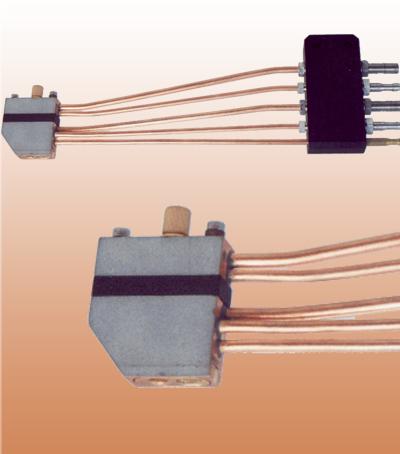

The PP-21 PTA torch has a flat design and is purposed

for plasma transferred arc surfacing (the PTA-process) in hard-to-reach places of different parts (fillet of shaft, narrow

chink and etc.).

It is possible to deposit Fe-, Ni-, and Co- based alloys.

To avoid an electrical contact between PP-21 and hard-faced

part its side surfaces are covered by ceramic. |

The PP-21-01 PTA torch is modification of the PP-21.

The difference is in holder.

Pure argon (99,995% Ar) is used as a working gas.

I. Technical data of PTA torches

| Parameters |

PP-21 |

PP-21-01 |

| Current of pilot arc,

A |

20 - 30 |

20 - 30 |

| Current

of transferred arc, A |

20 - 150 |

20 - 150 |

| Additive powder

deposition rate, kg/h |

0,2 - 2,0 |

0,2 - 2,0 |

| Powder particle

size, mkm |

63 - 150 |

63 - 150 |

| Powder losses, % |

<

6 |

<

6 |

| Total gas flow rate (argon),

l/min |

11 - 14 |

11 - 14 |

| Cooling water flow rate,

l/min |

>

2 |

>

2 |

| Thickness x height, mm |

16 õ 71 |

16 õ 71 |

| Weight without holder(with holder), kg |

0,4(0,7) |

0,4(1,1) |

| II. The PP-21 PTA torch schematic

view |

|

| The PP-21-01 PTA torch schematic

view |

|

| III. The PP-21 PTA torch exploded

view |

|

| Example

of application |

PP-21 |

Drilling bit legs

|

- for outside surfacing PP-6-01 ·

PP-6-02 ·

PP-6-03 ·

PP-6-03M ·

PP-6-04 ·

PP-7 ·

PP-7-01 ·

PP-7-02 ·

PP-8 ·

PP-9S

- for inside surfacing PP-12 ·

PP-12-01 ·

PP-14 ·

PP-15

- for special purpose

PP-9L ·

PP-21 ·

PP-21-01 ·

PP-25

|