|

The Plasma-Master Co., Ltd. has developed the technology

and also materials and the equipment for PTA-surfacing

of extruder and heat softening device screws. The

offered technology may be used with success both at

manufacturing of new details, and at restoration of

the worn-out parts.

Essence of a method

The essence of a method consists in deposition of

wear proof and corrosion-resistant material directly

on a crest of turn of screw.

|

The plasma transferred

arc is used as a source of heating, the small-grained

powder blown into an arc by a stream transported

gas serves as an additive. Working gas - argon. |

Materials

Due to application of powder that is specially developed

for these purposes from the Fe-base

alloy PM21, the surfacing is conducted without

preheating of part practically in all range of diameters

from 32 up to 320 mm. It essentially simplifies technology

of surfacing.

Service life of screws surfaced by PM21 alloy raises

in comparison with nitrated screws in 3-5 times. PM21

alloy replaces expensive Stellite successfully that

is used abroad traditionally.

|

|

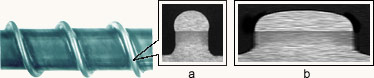

screw after use screw after surfacing

a - macrosection of surfaced screw turn without

vibration of plasma torch

b - macrosection of surfaced screw turn with vibration |

|

Characteristics

Surfaced metal combines high wear resistance, durability

and the plasticity, allowing to avoid occurrence of

cracks not only during surfacing but also in exploitation.

It is not inclined to tear and works with a nitrated

layer of the cylinder well. Hardness of metal after

surfacing is 43...45 HRC. After tempering at t ° =

650 °С, 1h its hardness raises up to 50...53 HRC.

The sizes of surfaced coat can be adjusted over a

wide range, changing of quantity of supplied additive

powder, amplitude of vibration of plasma torch and

speed of surfacing. Due to good formation of surfaced

metal the minimal allowance on the subsequent machining

is reached. At correctly chosen surfacing mode the

share of the basic metal does not exceed 5 %.

The

rate of use of an additive powder is 95 %.

Equipment

PTA system based on PM-300

PTA system based on PM-300

|

The equipment created

on the basis of the PM-300

PTA surfacing module is used for PTA-surfacing of

screws. The screw-cutting lathe or any other mechanism

may be used for detail rotation and device moving

relative to the turn. The type of the machine

is usually caused by the maximal sizes of surfaced

parts. |

One operator carries

out the surfacing mainly in a semi-automatic mode.

However for surfacing of parts with complex geometry

of a turn or in places of transition from one

step on another, surfacing may be conducted in

a manual mode. Connection of additional PP-25 manual

PTA torch is provided for this

purpose in the PM-300 PTA surfacing module.

|

PP-25 application

PP-25 application |

Many years experience of this technology using

has shown, that it is a highly effective, reliable

and economic way to increase the durability of a part.

Also see:

PM-300 PTA surfacing module

PP-25 - PTA torch for manual

surfacing

PMalloy 21 - Wear-resistant Fe-based

alloy

services: PTA-surfacing

science: Plasma

transferred arc surfacing (PTA-surfacing)

|