|

1 · · · 2

· · · 3

· · · 4 · ·

· 5 · · ·

|

|

|

| Plasma

transferred arc surfacing (PTA-surfacing) |

Being a modern advanced technology, the plasma transferred

arc (PTA) surfacing is used wide to coat function areas

of high responsibility details with special materials, which

are resistant against intensive wear, corrosion, thermal

and percussive loading.

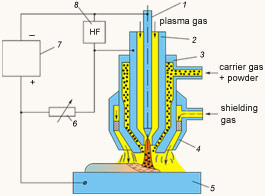

| PTA method schematic illustration |

|

1. Electrode

2. Plasma nozzle

3. Focusing nozzle

4. Shielding nozzle

5. Work piece

6. Ballast resistance

7. Power source

8. Oscilation unit

|

The pilot arc is ignited generator between non-consumable

tungsten electrode and so called, plasma forming nozzle

with the help of high voltage. The pilot arc, in its turn,

creates the transferred arc between tungsten electrode the

treated detail. The transferred arc is constricted by the

plasma forming nozzle, getting higher temperature and concentration.

The additive powder is fed into the arc column.

It is possible to regulate process conditions so, that

the whole amount of powder and only a thin film on the detail

surface are melted. As a result, a metallurgical bond between

cladded layer and detail is provided with the minimum dilution

of the detail material (3-10%). Ar is basically used for

arc plasma supply, powder transport and molten material

shielding.

Comparing with conventional arc surfacing technologies

the PTA offers:

- high deposition rate up to 10 kg/h

- high quality of deposited metal

- minimum penetration into base metal (< 5%)

- minimum losses of filler material

- deposits between 0,5 - 5,0 thickness and 3,0 - 50,0

mm width can be produced rapidly in a single pass

- Fe-, Ni-, Co-, Cu- base alloys as well as composite

materials can be clad

In a competition with the laser surfacing the PTA technology

offers much more high productivity, comparable high quality

of deposits and significantly lower costs.

Typical application areas of the PTA technology

|

extruding machine screws

|

valves of internal combustion engines (motorcar,

marine, locomotive etc.)

|

|

|

|

|

cutting tools (milling cutters, broaches, knifes)

|

quid roll fittings, accessories for ships, petroleum

chemistry and power generation, hydrotransport, pump

plungers etc.

|

|

|

|

|

Also see:

services: PTA-surfacing

1 · · · 2 · · ·

3 · · · 4

· · · 5 · · ·

|