The control system of PM-150M designed on a PLC.

Due to availability of the PLC it is possible to use PM-150M as an automatic system.

For this purpose additional machine PTA torches are provided.

PM-150M PTA system adapted for hardfcaing of small valves

Example of the system for hardfacing of small parts for stop valve in automatic mode.

PM-150M PTA system with robot

This photo shows robotic set-up at TMC Poland (Poland) for hardfacing of different parts in automatic mode.

PM-150M PTA system adapted for hardfacing of diesel valves with using of PP-7 PTA torch

At the photo you can see the PM-150M adapted for hardfacing of diesel valves in automatic mode.

The PTA torch with mechanical oscillator is installed on stand with capability of vertical moving.

Length travel of the PTA torch is provided by the oscillator carriage in range of

100 mm.

It is possible to hardface with this equipment faceplate, cylindrical and conical surfaces of different outsize parts.

Control all mechanisms is provided from one remote-control station.

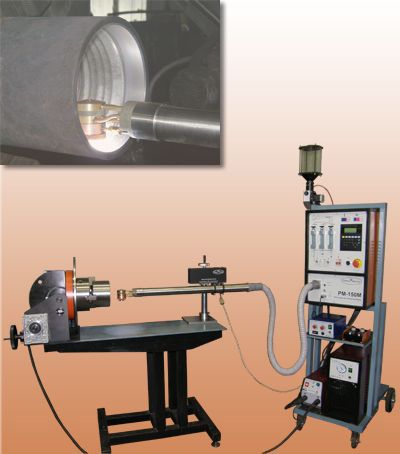

PM-150M PTA system adapted for surfacing of cylindrical details with using of PP-12 PTA torch

Example of the system for surfacing of bore with length up to 700 mm and inner diameter above 100 mm.

|